Plastic

Automation plays a crucial role in the plastic industry, enabling tasks such as injection molding machine automation and the assembly of injection molding machines. UniLogic excels in integrating automated processes into plastic processing, reducing production time, and enhancing safety.

Precise temperature control is of paramount importance in various plastic processing operations, including injection molding, blow molding, extrusion, and thermoforming. UniLogic addresses this need by providing the plastic industry with robust temperature control, control loop tuning, and closed-loop control solutions. Our expertise ensures fully functional and efficient processes, helping plastic manufacturers optimize their operations.

In addition to temperature control solutions, UniLogic also offers advanced parison control for the plastic industry. Parison control is a critical aspect of blow molding operations, where a hollow plastic tube (parison) is inflated to form the desired shape of the final product.

UniLogic’s parison control solutions ensure accurate and consistent control over the parison’s dimensions and wall thickness during the blow molding process. By precisely managing the parison’s inflation, UniLogic helps plastic manufacturers achieve uniformity in the finished products, minimizing material waste, and optimizing production efficiency.

With UniLogic’s automation expertise, plastic manufacturers can seamlessly integrate parison control into their blow molding operations, resulting in improved product quality, reduced defects, and enhanced overall process control. Our tailored solutions enable the plastic industry to meet strict quality standards, increase production output, and remain competitive in the market.

By partnering with UniLogic, the plastic industry can benefit from comprehensive automation solutions that encompass temperature control and parison control, enabling manufacturers to streamline their operations, enhance product consistency, and ultimately achieve higher levels of success.

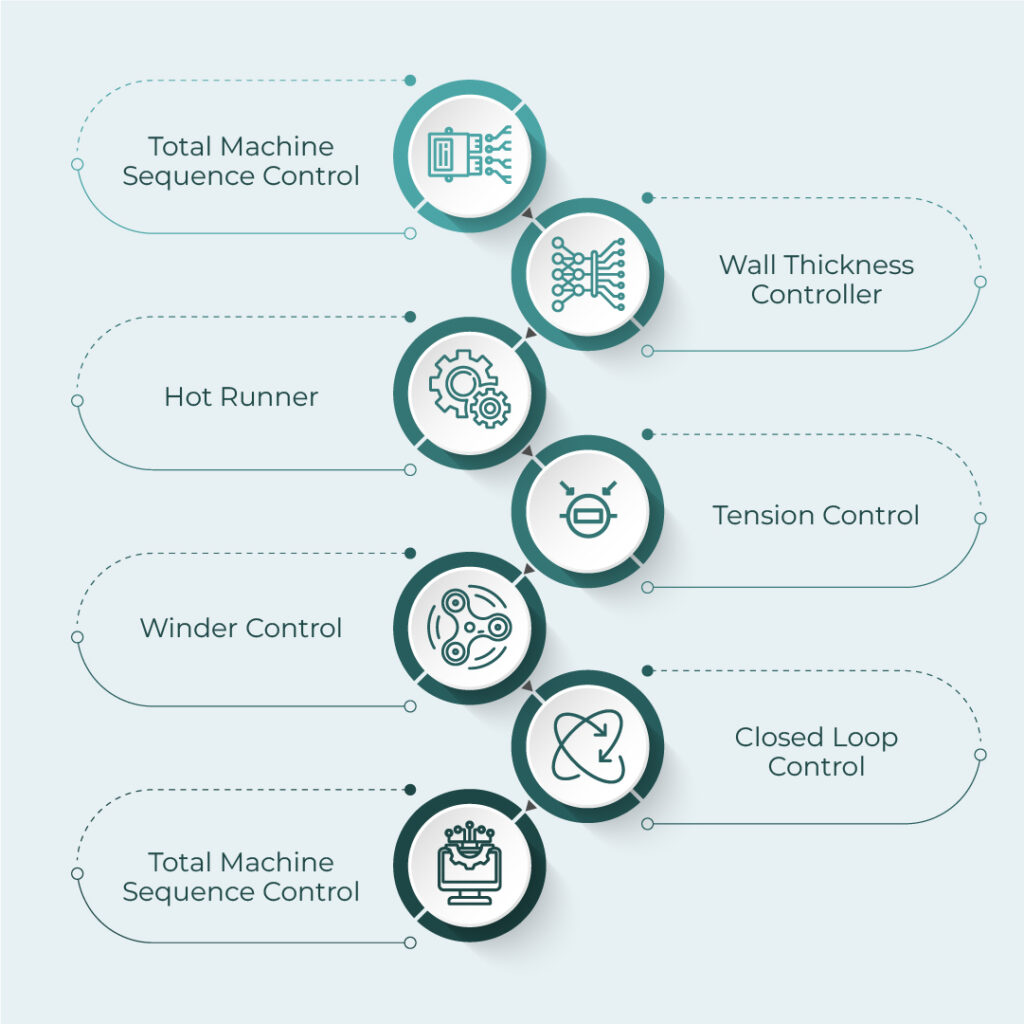

UniLogic offers a variety of solutions for the plastic industry including: